Why Use Lean Six Sigma When Planning Complex Change

Why Lean Six Sigma Works for Complex Change Management

Table of Contents:

Complex change is difficult to execute well. Organizations introduce new systems, redesign processes, or restructure teams with good intentions, yet many of these initiatives fail to deliver lasting results. The issue is rarely effort or intelligence. The issue is how the change is planned.

Many companies approach process and business problems reactively. A workflow slows down, errors increase, or reporting becomes unreliable.

The response is often to

- add a tool,

- build a workaround, or

- push teams to move faster.

These actions create activity, but they don’t always create improvement. Over time, these quick band-aid fixes add complexity, increase variation, and make problems harder to see.

At Polished Geek, we help your company solve process and business problems forma very different methodology with Lean Six Sigma.

Lean Six Sigma is a methodology that provides a structured way to plan change which reduces risk and increases buy-in along with the likelihood of measurable results.

A Structured Way to Solve Business Problems

Lean Six Sigma starts with clarity.

Before redesigning anything, it defines the problem in operational terms. Teams identify where work flows, where it stops, and what outcomes matter most.

Decisions are grounded in data, not assumptions.

This matters because many change initiatives begin with solutions. Teams select software, design new workflows, or introduce governance without fully understanding the problem they’re trying to solve. When that happens, inefficiencies get automated, confusion gets standardized, and misalignment spreads across teams.

Lean Six Sigma creates discipline early in the process. It helps teams align on what success looks like, what constraints exist, and where effort will have the greatest impact. That clarity sets the foundation for effective change.

Managing Complexity Through Systems Thinking

As organizations grow,

- Complexity increases

- Teams develop their own ways of working

- Data lives in multiple places

- Ownership becomes unclear

- Hand-offs introduce delays

- Reporting requires manual effort to reconcile inconsistencies

Lean Six Sigma (LSS) treats these issues as system problems. It looks at how work moves across teams rather than optimizing each team in isolation. LSS identifies 8 wastes that slow execution and create frustration, including unnecessary approvals, duplicate data entry, rework caused by missing inputs, and waiting for decisions with no clear owner.

When planning a change initiative, this perspective is critical.

Every new process or rule should simplify execution. Lean Six Sigma provides a framework to evaluate whether a change removes friction or adds to it.

This approach helps leaders make fewer decisions, with better outcomes.

“Isn’t Six Sigma just for Manufacturing?”

Yes, Six Sigma did originate in manufacturing, but the principles apply to any environment where work flows through a system. Digital and service organizations have processes, handoffs, delays, errors, and rework, even if no physical product is involved. The difference is how waste shows up.

In digital and service environments, waste often appears as waiting for approvals, searching for information, duplicating updates across tools, unclear ownership, and work being sent back for revisions due to missing context.

These issues slow execution and frustrate teams, yet they’re often treated as normal parts of work. Read more about 8 wastes.

Lean Six Sigma helps teams identify and reduce these forms of waste by making work visible and measurable. The focus shifts from output volume to flow, quality, and consistency.

Designing Change That Delivers Results

Many organizations declare success when a change is launched, a new system goes live, a process is documented, or a training session is completed. But what about when performance doesn’t improve, do they know?

Lean Six Sigma ties change directly to outcomes. It defines metrics early and uses them to guide decisions throughout the initiative.

These metrics might include

- Cycle time,

- Error rates,

- Throughput, or

- Visibility into work in progress.

Clear measurement allows teams to adjust quickly. Leaders can distinguish between normal adoption challenges and structural issues that require correction. Over time, this creates confidence in both the change and the data used to evaluate it.

Supporting Adoption Through Practical Design

Processes fail when they don’t reflect how people actually work.

Lean Six Sigma incorporates the people doing the work into the design process and involves co-creation. It captures real workflows, real constraints, and real dependencies. Solutions are built to support execution, not theory.

This approach improves adoption because teams understand the logic behind the change. They know what’s expected, where work lives, and how decisions move forward. The system supports them instead of slowing them down.

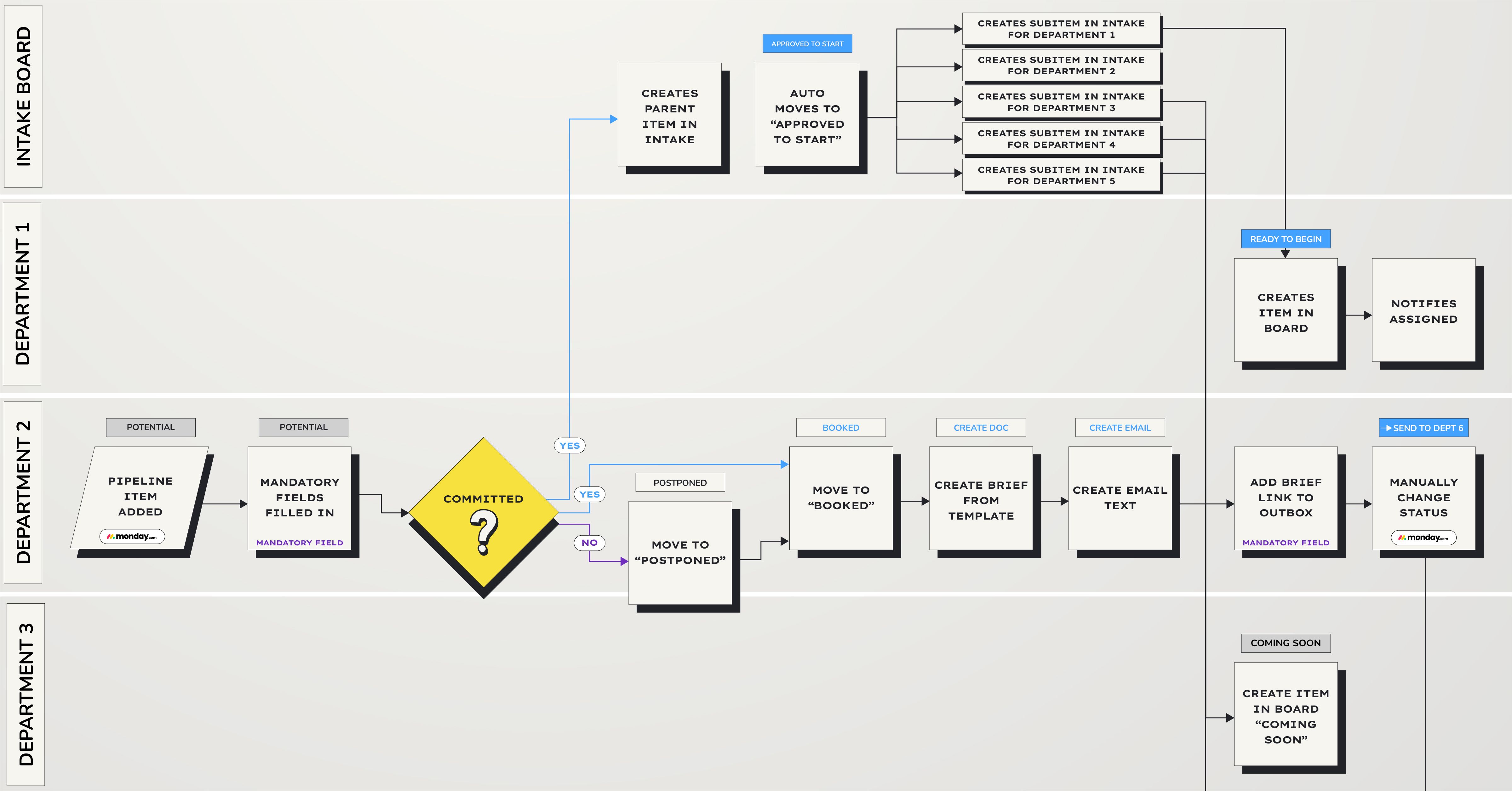

This is especially important when implementing platforms like monday.com. Tools amplify whatever system they’re built on. Lean Six Sigma ensures that system is intentional.

Planning Change Instead of Reacting to Problems

Lean Six Sigma is often associated with fixing broken processes. Its greatest value comes from planning change before problems scale. It helps organizations slow down at the right moments, ask better questions, and avoid rework later.

When applied early, Lean Six Sigma can:

Reduce false starts,

Prevent over-engineering, and

Create alignment across teams.

Change will then become easier to manage because decisions are made with full visibility into downstream impact.

This approach saves time, reduces frustration, and increases confidence in execution.

Need help with your change?

At Polished Geek, we use Lean Six Sigma as the foundation for how we approach complex change. We begin by understanding your business as a system. We map how work flows today, identify where it breaks down, and define what success means for your organization.

Our team combines Lean Six Sigma, change management, and monday.com expertise to design solutions that scale and are adopted long-term. We help organizations reduce waste, improve visibility, and create systems their teams trust.

If you’re planning a complex change and want a structured way to reduce risk, we invite you to book a free consultation. It’s a working session to discuss your goals, your challenges, and whether our approach fits your needs.

Complex change requires intention.

With the right structure, it becomes a driver of clarity, efficiency, and growth.